Do you have multiple fields close to each other that can be applied from a single takeoff point? We recommend the Multitask function, which we explain in more detail in this article.

What is the Multitask function?

Multitask is one of the new features brought to us by the DJI Agras T50 and DJI Agras T25 drones. The feature allows you to schedule and select multiple fields at once to apply without any interruption of the work and edit the missions prepared for the Agras.

How does it work?

The first step is to see if we have the right conditions for this function:

- Fields next to each other: for this function it is better and safer if the fields are bordering each other or separated by only a few meters. When the drone finishes the first field and the balance is enough to start working on the second one – the drone will move itself to the second field, which is pre-arranged and planned, and start applying. The ideal case is, for example are fields with biostripes. Instead of creating 2 fields that need to be set up separately and, after one mission is completed, turn on the species – the Multitask function allows you to select both missions at once, with the same parameters and without the need for additional stopping or setting up.

- Distance and battery life: in case of residual spray liquid in the tank, it is necessary to monitor also the remaining % of battery in case of insufficient flight endurance in case of longer distance between parcels or between the take-off point and the second mission

- Obstacles: it is much safer to use Multitask for fields that are closer together, but the key point is also obstacles that could pose some danger when moving from one mission to another. We recommend that you pay close attention to and especially prepare for the missions

How to set it up?

- Planning and preparation of fields

First of all, we need to have the fields we would like to use ready before running the function itself.

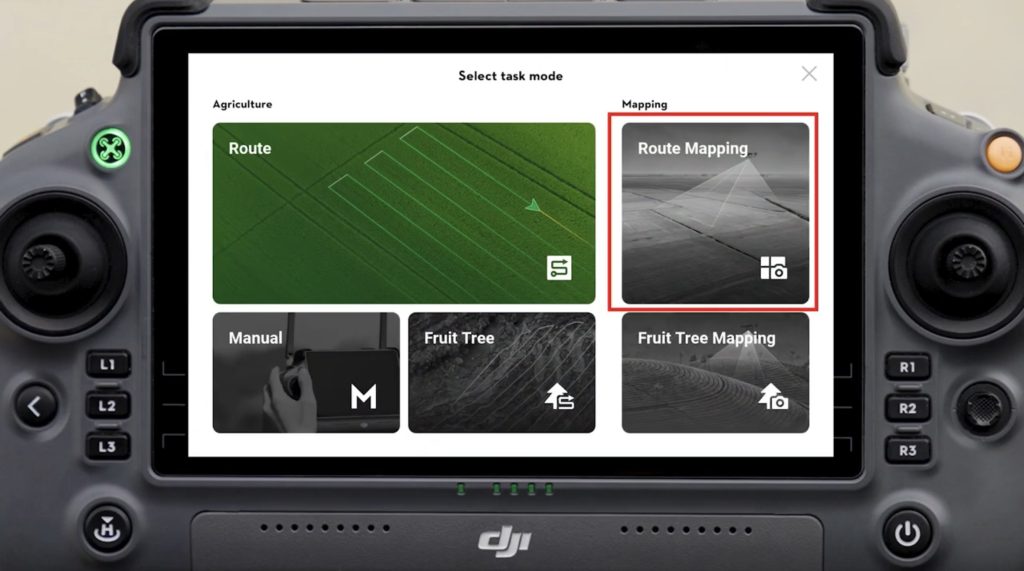

The fields can be prepared using RC – to create them you need to click on ROUTE MAPPING in the menu or go to the maps via the “Begin” button on the home screen.

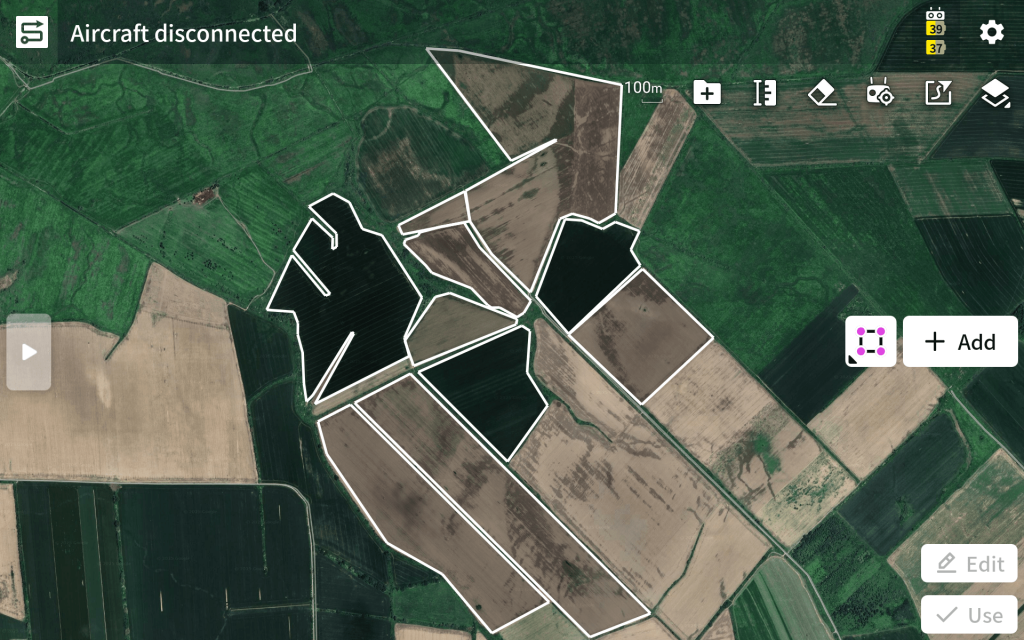

The next step is the selection of the tools and the preparation of the fields themselves:

Click on the “Add” button on the map background screen, after clicking you will have three options to choose from – Crosshair, Controller or Aircraft.

In case the available base map will be sufficient for you to prepare the fields – choose the “Crosshair” option.

The next step is to prepare and enter the boundaries of the field – according to the position of the crosshair on the map we will click the boundaries.

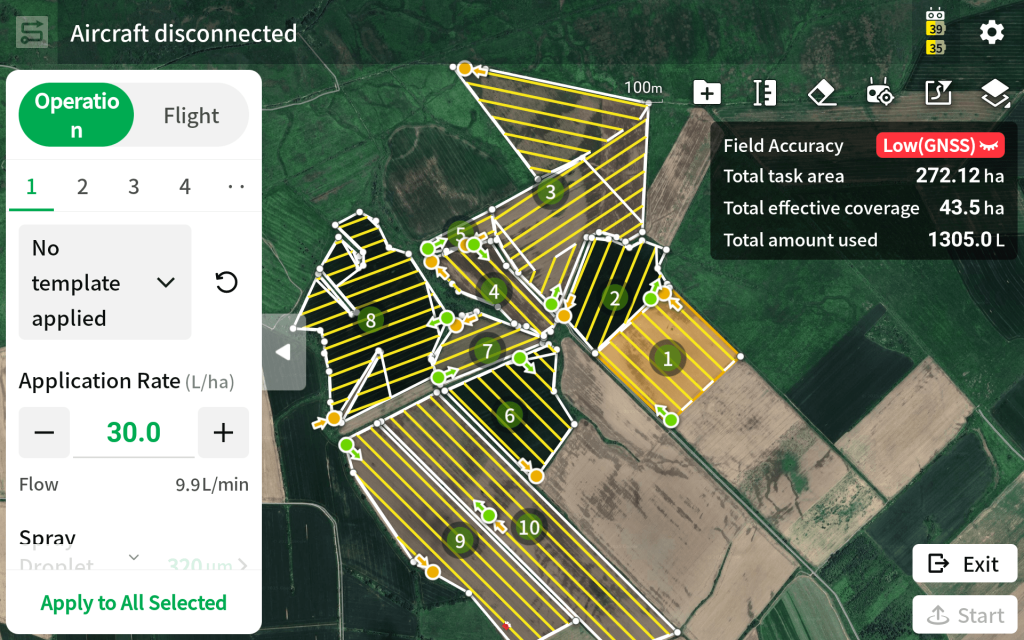

this is what the prepared fields may look like:

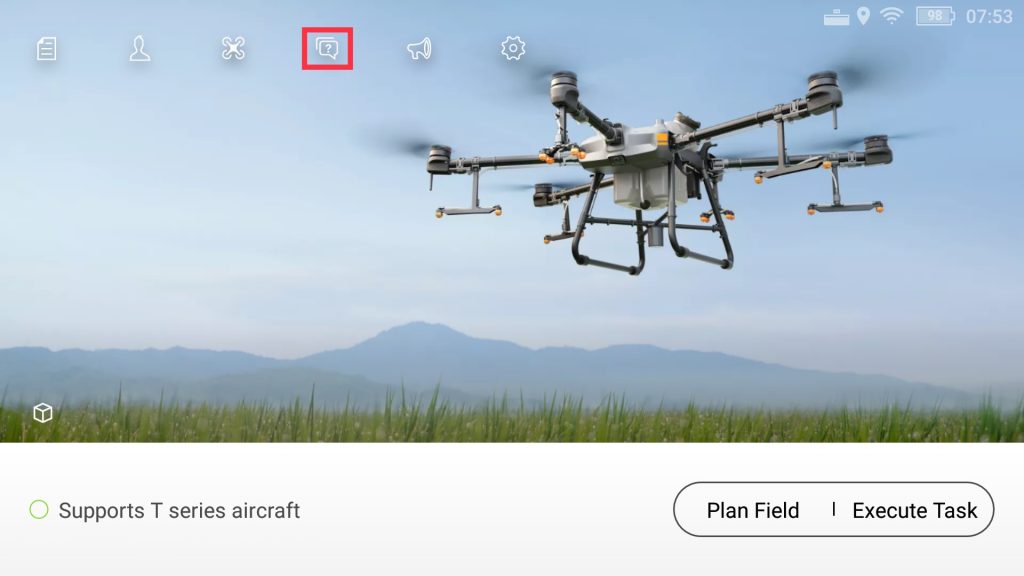

- Switching on the “Multitask” function

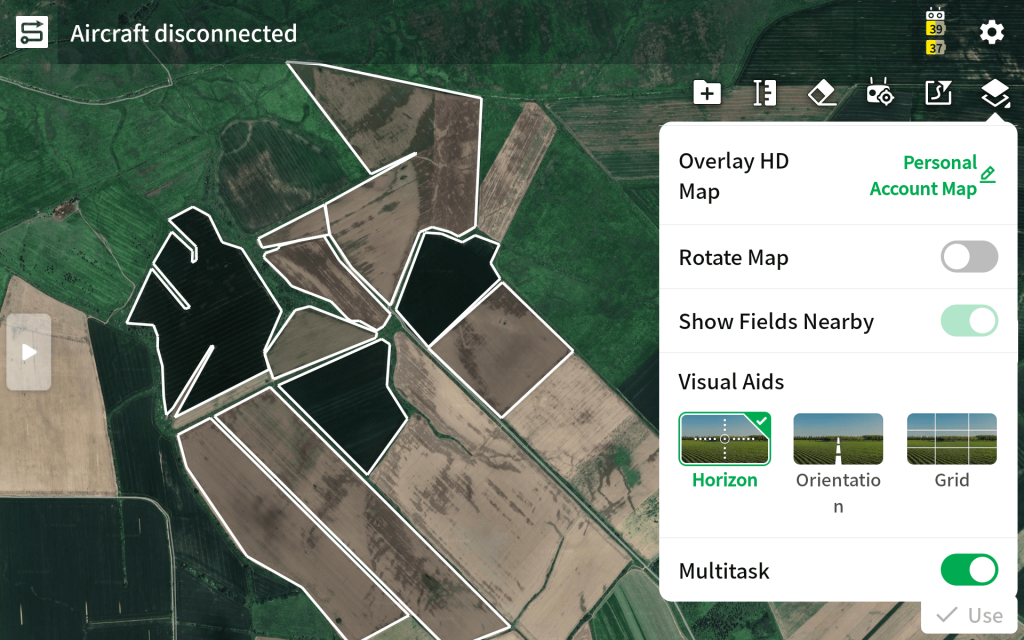

After you have prepared the necessary fields, you need to turn on the Multitask function itself

In the top right corner of the screen there is a button showing the squares one above the other, when you click it a table will pop up where you will find the option to turn on the Multitask function.

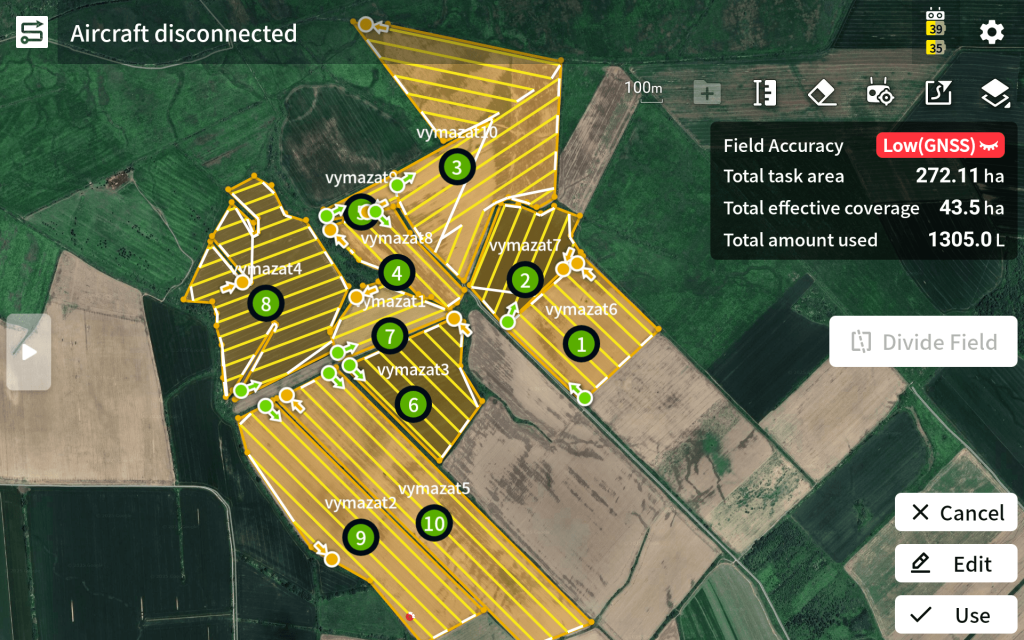

- Selecting the fields we want to use for the application

In case the feature is enabled, the next step is to select the fields for the application itself. The maximum number of fields we can select is 10 !

The selection is done by simply clicking on each field we want to use.

After selecting all the fields, you will also see the total area of these fields and the total amount of substance needed for these fields (however, this varies depending on the set dose)

- Setting the parameters of the fields

The next and final step before starting is to set the parameters for the field application.

Parameters can be set separately, a different setting for each field, or the same parameter setting can be selected for all fields.

The parameters are set as follows:

- rate per hectare

- droplet size

- the spray width

- flight speed

- flight height

After setting all the parameters, you are ready for the application itself – all you have to do is click the Start button and the Multitask function is ready.

For more articles or tutorials like this, be sure to follow us on social media or subscribe to the site.

Instagram – https://www.instagram.com/enterra.sk/

Facebook – https://www.facebook.com/enterra.sk/

Youtube – https://www.youtube.com/@enterra7820

DJI drones are powered exclusively by rechargeable batteries, which are a key element of their performance and reliability. While DJI engineers have achieved excellence in battery quality and durability, their long-term effectiveness also depends on proper use and maintenance.

In this article, you will find the most important recommendations for storing, transporting and troubleshooting potential problems with batteries that are compatible with DJI Agras drones. For example, the battery for the DJI Agras T50 drone.

Battery storage instructions

- Charge level during storage

- Charge the battery to 100% capacity before storage, after some time the battery will go into sleep mode

- Never store the battery fully discharged to prevent damage to the cells.

- Fully charge the battery every 3 months to keep it in optimum condition.

- Recommended storage temperature

- Keep the battery in an environment with a temperature of 5°C – 35°C.

- Temperatures below -15°C will self-discharge, which can damage the battery

- Storage environment

- Store batteries in a dry place, away from heat sources.

- Place the battery on a flat surface to prevent deformation.

- Avoid storage near flammable or explosive materials.

- Arrangement of batteries

- Do not stack the batteries on top of each other – there should be a distance of at least 30 cm between them.

- If you use racks, check their load capacity to prevent damage to the batteries.

- Checking the battery status

- Check the battery regularly to make sure it is not overheating.

- In case of excessive overheating, remove the battery immediately and contact service.

- The storage area should be equipped with fire extinguishing equipment.

- In the event of a fire, extinguish the battery and then dip in salt water for 24 hours.

- Appearance and cleaning of the battery

- After use, clean the battery with a dry or wet towel and remove any dirt.

- Clean the battery connectors with a cotton swab soaked in 95% alcohol.

- Check that the battery is not inflated, dented or deformed by more than 2 mm. If this is the case, do not use it.

Transportation of batteries during daily operation

- Use covered and enclosed vehicles.

- The battery must be removed from the drone and stored securely when transporting.

- Charging the battery using the generator in the car is not allowed during transport.

- The vehicle should be equipped with fire extinguishers.

How to troubleshoot DJI battery technical issues?

If you experience technical problems during use, please follow these steps:

- Software check

- Check that all components are up to date – remote controller, drone and battery.

- If an update is required, please do so with a stable internet connection.

- Charging test

- Try fully charging the battery with the original charger and check the charging time if necessary.

- Test in drone

- Charge the battery to 100%, insert it into the drone and perform a test flight.

- Fill the drone tank with 20 litres of water to ensure the drone is loaded.

- Lift the drone and discharge the battery from 100% to 24% (flight takes approximately 5 – 7 minutes).

- Check if the controller indicates a battery error.

If, after all the steps, the battery still does not work properly, proceed as follows:

1. Prepare 6 photographs of the battery (including details of damage).

2. Fill in the service form. (to fill it out click HERE!)

3. Ship the battery to the DJI service address listed.

DJI Agras Series Authorized Service Address: https://www.enterra.sk/en/our-contacts/

Conclusion

Following proper procedures for storing, transporting and using DJI batteries extends their life and reduces the risk of technical problems. In case of any complications, follow the steps above or contact DJI official authoriozed service.

The DJI Agras T50 and DJI Agras T25 appear to be drones that could replace the T30 and T10 models — one being smaller with lower power, the other larger with higher power. But is that really the case? Is the Agras T50 a successor to the Agras T30, and similarly, is the Agras T25 a replacement for the Agras T10?

In this article, we will analyze the actual performance and applications these new models bring to the market.

DJI Agras T50 – The New Standard in Performance

The DJI Agras T50 is indeed a significant step forward. Besides a larger tank capacity, increased speed, and substantially higher power than its predecessor, the Agras T30, it brings many new features and improvements to the drone itself.

With innovations such as centrifugal nozzles, an entirely new spraying system, and an enhanced radar system that offers more precise terrain and obstacle detection, the Agras T50 is a true 3-in-1 autonomous unit — capable of spraying, spreading, and mapping. Considering its performance capabilities and technological innovations, the DJI Agras T50 has become an unrivaled leader in the agricultural drone segment.

DJI Agras T25 – A Small Drone with Big Capabilities

The DJI Agras T25 is often compared to the T10 model, as it’s the smaller drone in DJI’s lineup. However, the T25 offers considerably higher performance, with capacity closer to that of the T30.

In terms of technological innovations, the T25 also far surpasses its predecessors, similar to the T50. Performance-wise, the Agras T25 is more comparable to the T30, with a 7-meter spray width, a maximum speed of 36 km/h, and a 20-liter tank, delivering a practical capacity of 12-13 hectares per hour. In contrast, the frequently compared T10 has a 5-meter spray width, a maximum speed of 25 km/h, and an 8-liter tank, achieving around 6 hectares per hour. Therefore, the T25 performs on par with the T30.

So, What’s the Conclusion? Is the T50 a Replacement for the T30, and the T25 for the T10?

In conclusion, the DJI Agras T50 and T25 are not direct replacements for the previous models. The T50, with its performance and technological enhancements, greatly outperforms the T30, making it DJI’s flagship agricultural drone and setting new expectations for this type of device.

The DJI Agras T25, while smaller, delivers high performance that can match the previous Agras T30 model. However, only in terms of performance; if we consider the technological improvements and functions of the T25, even the T30 is not an ideal model for comparison.

Both models indicate DJI’s direction and represent significant advancements in the development of smart drones for agricultural purposes.

You can find more informations about the DJI Agras T50 and T25 drones at these links: https://www.enterra.sk/en/product/dji-agras-t50/ , https://www.enterra.sk/en/product/dji-agras-t25/ or you can read interesting information about our impressions after half-year testing of the T50 at https://www.enterra.sk/en/dji-agras-t50-first-impressions-after-six-months-of-testing/.

Save Manual Operations as automatic plots

The flight path from a manual flight or a manual boundary flight can now be saved as a field with one click for automatic use later. This is helpful for small plots, where you can fly once and save it for repeated use. Pilots can save time on larger plots by manually spraying field boundaries and automatically spraying the rest of the field.

Notes:

- The green track on the outermost circle determines the coverage area of the plot. Ensure that the edges of the plot are covered by the green track to avoid omissions.

- When using this function to encircle the plot, since the edges have already been sprayed, be sure to edit and adjust the route separately (route spacing, margin, boundary spraying, etc.) to avoid overspraying or missing spots.

Add Marker Lines and Points

When planning flight routes, you can now add marker lines and points to points of interest on the map.

Application Examples:

Marker Lines: Can be used to mark the location of power lines within the plot, making it easier to track their location relative to the drone during operations.

Marker Points: Can be used to mark objects in fields, making it easier to locate and find them quickly after covering the soil.

Notes:

- Unlike field boundary points and obstacle points, marker lines and points do not affect route planning or flight operations; they are only used for position display.

- Marker lines and points cannot be saved separately. They need to be added to boundary points and saved as a plot.

Low Speed Ascend at the start point

After a refill or battery swap, when the drone returns to the start point or break point, its propeller downwash at low altitude and speed may cause some crops to lodge.

After enabling Low Speed Ascend, the drone can descend and spray from the set Low Speed Ascend height, reducing the risk of lodging.

The start-spraying height is Operation Height plus Low Speed Ascend Height

Note:

- Enabling Low Speed Ascend will apply to all turns and starting points (breakpoints). Please use it only where there are no obstacles at the field boundaries and in the field.

Added Route Visualization function in M+ mode

In M+ mode, Route Visualization helps users find the breakpoint and align the drone’s direction according to guidelines. This helps users avoid route deviation and inconsistent spacing.

Note:

- To disable this feature, go to “Top Right Corner Settings – Aircraft Settings – Alert and Assist – Route Visualization (M+)” and choose to turn it off.

Task Summary is available in real time during operations

During operations, you can view task summaries in real-time, including completed work data, estimated chemical usage, and the remaining work to be done.

Multi Plot Operations get some optimizations

Multi Plot Operations now supports Empty Tank Point estimation and Automatic RTH.

When using Multitask, Empty Tank Point estimation can now span multiple plots, showing the estimated Empty Tank Point based on the actual volume of chemical left in the tank.

In addition, users can now select “Return Home After Completing Operation” when using Multi Plot Operations. Once enabled, the drone will automatically return to home after completing all plot operations.

Note:

- Smart Return to Home supports obstacle avoidance, but the success rate of obstacle avoidance varies with different speeds and obstacles. Please pay attention to the surrounding environment and avoid heights with power lines during return to ensure safety

Introducing Show Fields Nearby to help avoid overlapping

The new “Show Fields Nearby” function helps users avoid overlap by displaying nearby fields on the map during field planning. It also aids in manual operations, helping to avoid accidentally entering adjacent fields.

Spray/Spread When Turning on Orchard Routes

With Spray/Spread When Turning enabled, the drone will continue to spray while turning, improving edge spraying effectiveness.

Note:

- This is only effective when the orchard route planning mode is Standard. You can enable it in the remote controller app under “Route Settings – Advanced.”

Additional Updates:

- Takeoff is prevented during refilling, enhancing safety for ground crews and operators.

- During flight, pilots can press the orange pause button on the remote controller. This will cause the drone to pause automatic flight and enter hover mode.

- After landing, propeller rotation stops two seconds faster, increasing safety and reducing downtime.

- Added support to perform spreading at the fixed-spot routes in Fruit Tree Operation mode.

- Added support to disable atomized spraying in the Fruit Tree Operation mode.

- Added support to set the terrain scenario and flight parameters in the Task Settings on the left side of the screen when applying the task.

- Optimized the display of the flight trajectory in the app. The flight routes of the latest two flights are shown in the app during the operation.

- Added warnings when the propellers are abnormal.

We were excited about the arrival of the latest agricultural drone from the Agras range, the DJI Agras T50, but at the same time we were concerned about what to expect from the new features and overall performance of the drone.

As a leading dealer of agricultural drones, we had the opportunity to work with this drone and test its features for over half a year before its official launch.

In the following articles on our blog we will bring you detailed features, interesting facts, insights and most importantly the results of our field testing of the drone.

Have our fears been confirmed?

Our biggest concern was the change to a magnetic impeller driven pump as well as centrifugal spray nozzles, as we know that the biggest weakness on the previous DJI Agras T30 was the pumps and nozzles.

However, the fears did not come true, the change to this type of spraying system was justified and most importantly significantly more efficient.

The pumps do not come into contact with the spray liquid, which guarantees a longer service life of the pumps as well as a smoother operation of the nozzles.

Centrifugal spray nozzles also impressed us in a positive way, they can handle the application of thicker products, which was a problem with the previous model and which complicated the work of the drone.

New features

In addition to the new spraying system, the Agras T50 differs from previous models with added features.

The most important and most interesting is the mapping function. Thanks to the UHD camera, which has an adjustable angle, it is possible to map fields with the T50 and prepare a mission right in the field. This function is made possible by the new 8-core processor in the remote controller with a 7-inch display.

Compared to the Agras T30, the drone is significantly more agile and the movements during liftoff , return or during a mission are smoother – it feels as if you are controlling the drone even during automatic flight.

Is the 11-meter range realistic in our conditions?

The priority of our testing of the T50 was to see if, in the working conditions in which service providers find themselves, the drone can provide a steady 11-metre sweep and, more importantly, and even coverage of crops.

As is our custom in coverage testing, the testing was done under realistic conditions, with indicator papers and a number of combinations that can occur on the job.

The DJI Agras T50 did not disappoint, the 11-meter range is a reality and the coverage, which is the most important factor, is achieved. However, we will bring you a detailed analysis of our testing in future articles, as there are combinations of speed – droplet size – dose – width of coverage, which we prefer to avoid.

Conclusion

The DJI Agras T50 is the drone we’ve been waiting for. Not so much the increased tank volume as the amount of new features this model has brought us. The new features will guarantee you the efficiency and speed to get that promised 21 hectares per hour – yes, it’s possible.

We will bring you a more detailed analysis of the features and our testing in the following articles that we will prepare for you. Don’t hesitate to subscribe to our newsletter so that you don’t miss out on important information that could make your work more pleasant and easier in the future.

Already in 2019, we have encountered many complications and problems when entering the Slovak market with the provision of agrodrone services in agriculture. As the market was not and still is not fully accustomed to such technology in agriculture, one of these problems was the clientele and getting orders for these services. It is for this reason that we know what obstacles start-up entrepreneurs in this field have to go through. That’s why with our latest product, we decided to help everyone to have not only a start but also a whole “service career” much easier than we had it.

Access to contracts even without clients

The product that we want to introduce to you with this article is our BIRDU web portal. BIRDU is a portal that serves both service providers and service providers.

The idea of the portal is to make it possible for a new provider of these services, who is new to agriculture, for example, has no contacts, does not know how to get clients for these services, to get orders. Therefore, any customer who is interested in agrodron services can register on our portal and place a request for each application they are interested in, which can then be accessed by any service provider (sprayer). Thus, registered sprayers will be able to see every order from clients in their area (or an area they can determine in advance).

The customer enters, the service provider accepts

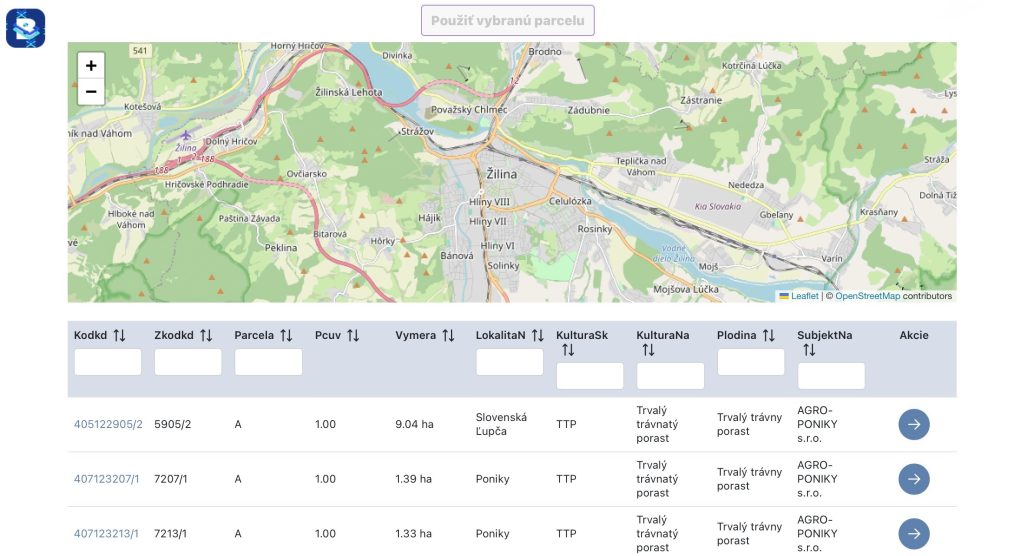

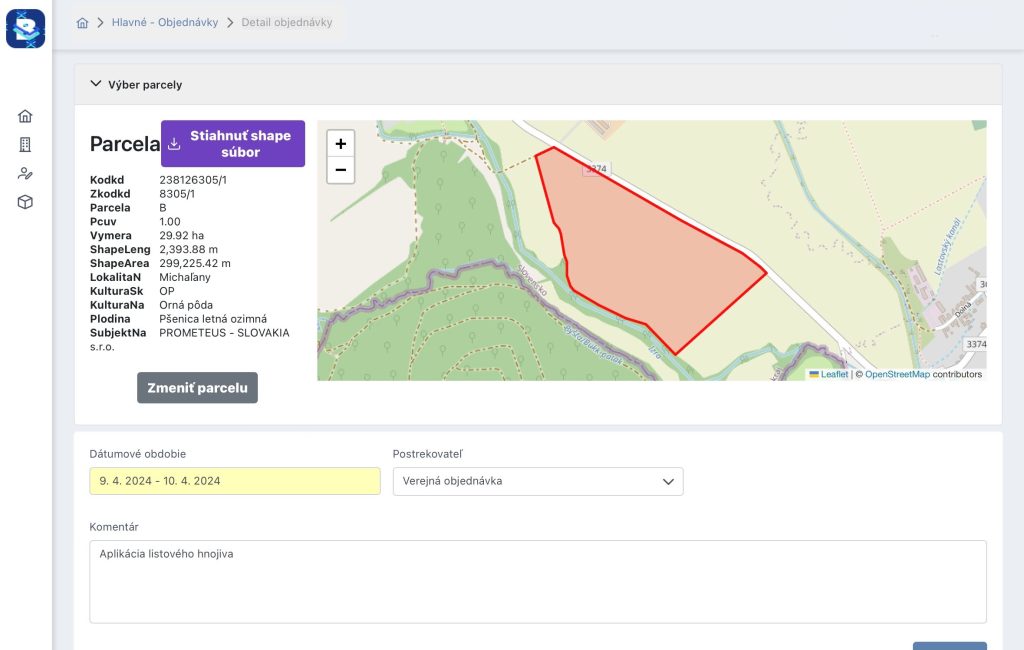

When entering the portal, the registered customer has the option to create a new order. When creating an order, it is necessary to choose the date period when he would be interested in the application agrodronmi. After selecting the date period, it is also necessary to select the specific parcel for which the order is created. This selection can be made on the map which will be displayed to the customer immediately after clicking on “new order”.

Then, when the customer has filled in the necessary information, he can choose the publication of the order from two options:

- Public

- Specific service provider

The customer has the option to choose to publish the order to the public, thus making the order available to every registered service provider in their area and thus ensuring a higher chance of the order being accepted by one of the many service providers or a particular service provider they may have been working with for a long period of time. The service provider then accepts the order and issues a quotation, which the client may or may not accept.

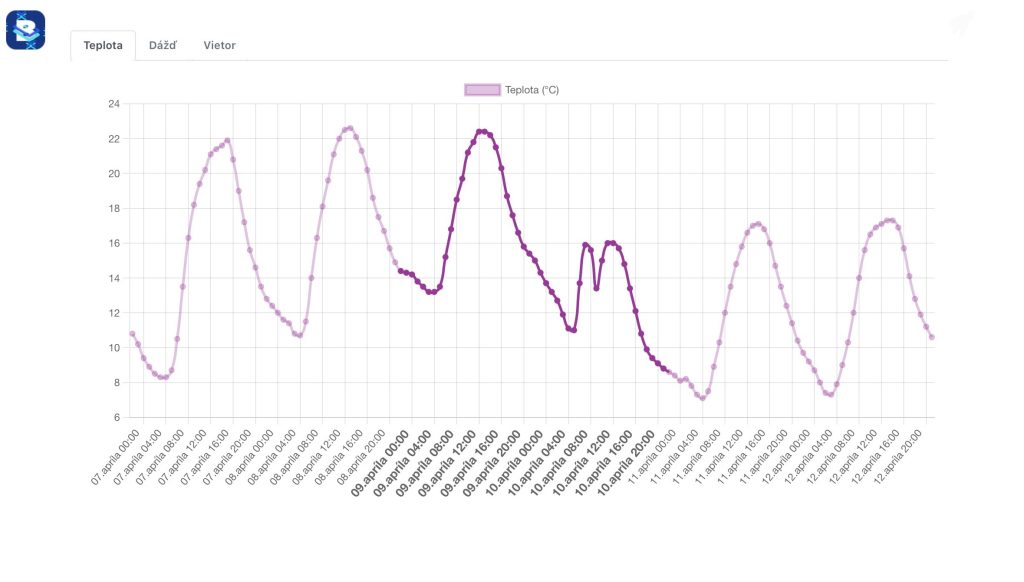

Weather

When ordering, it is also possible to monitor the weather for each day. If the customer has entered a date period in which they report unsuitable weather on the application, the sprayer can request a change to a date period specified by them. Thus, the weather feature can help avoid potential complications and delays on the part of the service provider.

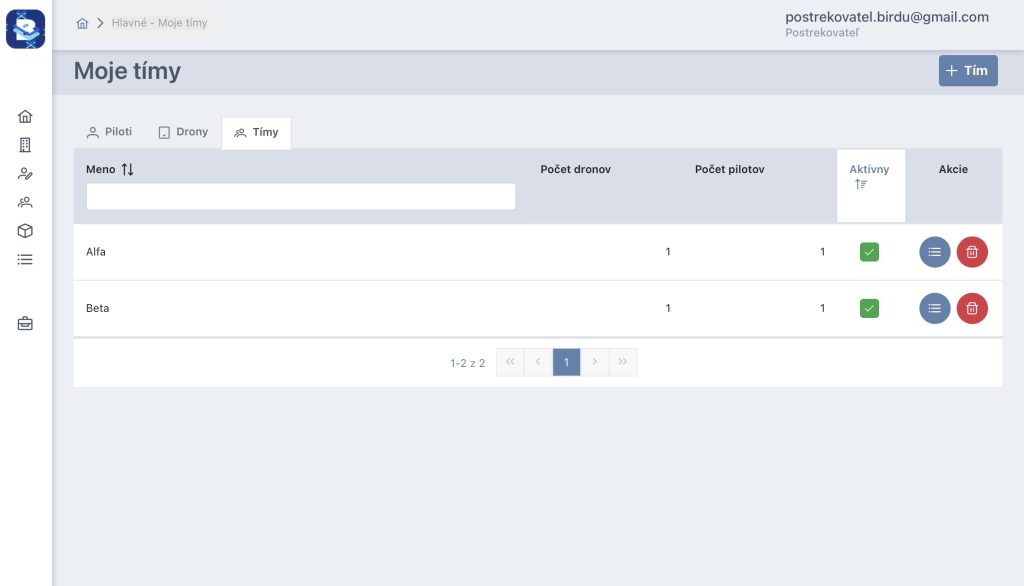

More agrodrones, more pilots, more teams

After registration, the registered service provider must also add a list of drones with pilots to their profile in order to be able to subsequently create a team that will be assigned to individual orders. When creating teams, the service provider first enters the number of agrodrones he has: the name of the drone and its serial number. Once the agrodrones have been entered, each pilot must also be entered: the name of the pilot and his average output per day and night (in hectares).

When the service provider enters the necessary information, he can create teams: the name of the team and also assign the pilot and agrodrone he wants to have in this team. More agrodrones, more pilots and more teams will of course give you more efficiency and more hectares flown.

Sub-order or postponement

If the deadline does not suit you as a service provider, you have the option of postponing or creating a sub-order on the portal.

Postponement means that if you are unable to execute an order you have the option of postponing it to another service provider, who will then invoice themselves once it has been executed.

However, if you have some partners who will execute the order on your behalf, for your client – you can create a sub-order. A sub-order is a feature in which your partner (the service provider you are working with) creates a quote for you and you, as the service provider, create a quote for the customer who has selected you for their order. In this function, the executor for the customer is retained, who will also invoice the order. But the executor will order their service provider to do the work.

Partner -> your company -> customer

This model is mainly used in case of congestion and with regular clients who are a priority for you.

Conclusion

To make working with the portal as easy as possible for you, we have prepared a video tutorial containing all the necessary functionalities and procedures for working with the portal.

You can watch the video on our website or YouTube channel.

In order to keep innovating and to attract as many people as possible in different sectors, not only in agriculture and industry, but also the general public, we try to invent and bring new products to our offer, which would have a use for example in travel, sports, fishing, etc..

As the exclusive and only dealer in the country, we bring to the market “Deeno”, a brand offering portable (electric) charging stations and solar panels.

If you work remotely, camp, go fishing or if the power is out at home, having access to a portable power source can help you significantly – that’s why we have decided to add similar products to our offer.

So what is Deeno?

In our range you’ll currently find the Deeno X1500 which is a portable charging station designed to fill the role for your off-grid adventures.

The big benefit is the high power capacity that this station offers. With a capacity of 1036 Wh and a power output of 1500 Watts, it can handle the demands of most home appliances.

When it comes to charging smartphones, laptops, or if you need to run your microwave or blender urgently – the Deeno X1500 can help you with that.

LiFePO4

The station is equipped with state-of-the-art LiFePO 4 technology, which ensures stability and efficiency in power supply. Lithium iron phosphate batteries have high energy density and low self-discharge values. One of the most important features of this type of battery is an electronic management system called BMS, which controls not only the charging and discharging of the battery, but also its temperature.

Thanks to this advanced technology, the station guarantees the endurance, reliability and stability you need for outdoor activities.

Practical design

The importance of user comfort is also ensured by the practical design that the Deeno X1500 offers. All input and output ports are easily accessible and labelled. Hidden handles make it easy to carry and transport the station so that you can get on your adventures without any hassle.

Features and amenities

LED light on the back of the station provides 4 modes of operation – 25%, 50%, 100% and SOS mode. In addition to the light, you also have a clear 4.3-inch LCD display that provides real-time information on power status, power, and time remaining.

A great advantage of this station is also the solar charging option – the optional portable solar panel uses the MTTP function and can charge the station in 6 hours.

Where can Deeno be used?

- Camping

- Hiking adventures

- Outdoor events

- Emergency power backup

- Travel

- Construction

- Life off the grid

- Boat trips

- Photo expeditions

- Days at the beach

- Sports events

- Fishing, hunting

- Medical facilities

From practice and service repairs it is known that 90% of accidents and problems with the drone are caused by the pilot and his improper handling of the drone, but there are also situations where the drone is at fault, or a fault that was not discovered during manufacture. In these situations, as an authorized service, we guarantee a repair under warranty (up to 2 years).

A step that will make this process easier and faster is the need to export post-accident data (logs)

Important notes

Immediately saving the data after encountering a problem will ensure the accuracy of the data transfer and avoid overwriting the data after switching the RC (controller) on/off several times, part of this step it is necessary to have the RC connected to the internet to synchronize the data during and after each flight.

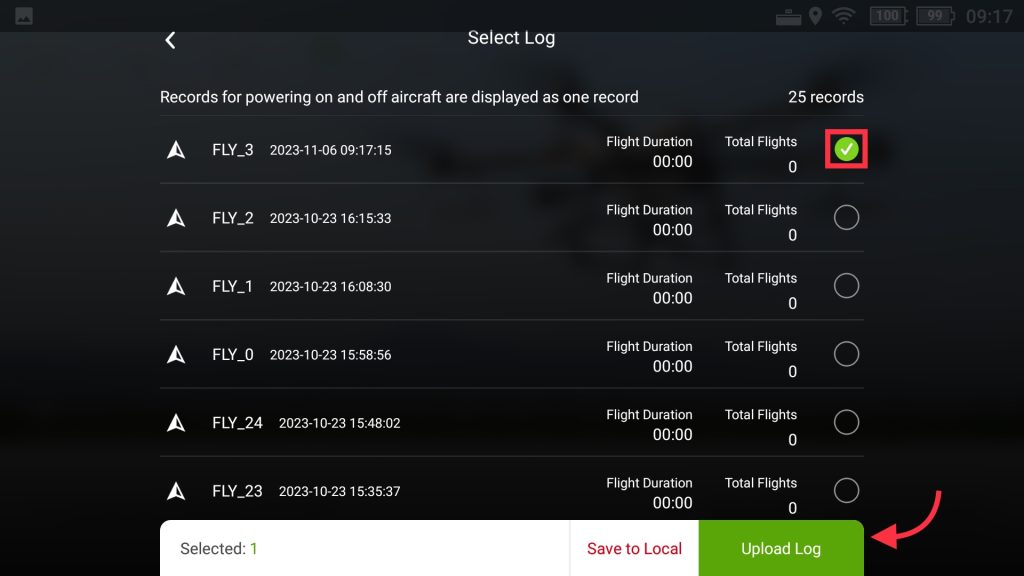

Due to storage space limitations, the data storage in the drone and the controller is different: the drone can store 25 logs while the controller can only store 10 logs.

This is why it is best to deal with the situation immediately after a problem arises and not to manipulate the drone further.

Preparation before uploading data

(These steps must be done in any case)

- Check the firmware version of the drone (if it is only a problem with the driver, this step can be skipped)

- Check the firmware version of the driver

- Description of the accident, error that occurred: at what time, during what conditions, during what operation, what error or problem occurred

- The time of the accident, it is necessary to know at least the approximate time when the problem occurred in order to send and check the correct data

How to export data

1. In the event of an aircraft accident, flight abnormalities, spraying and scattering abnormalities

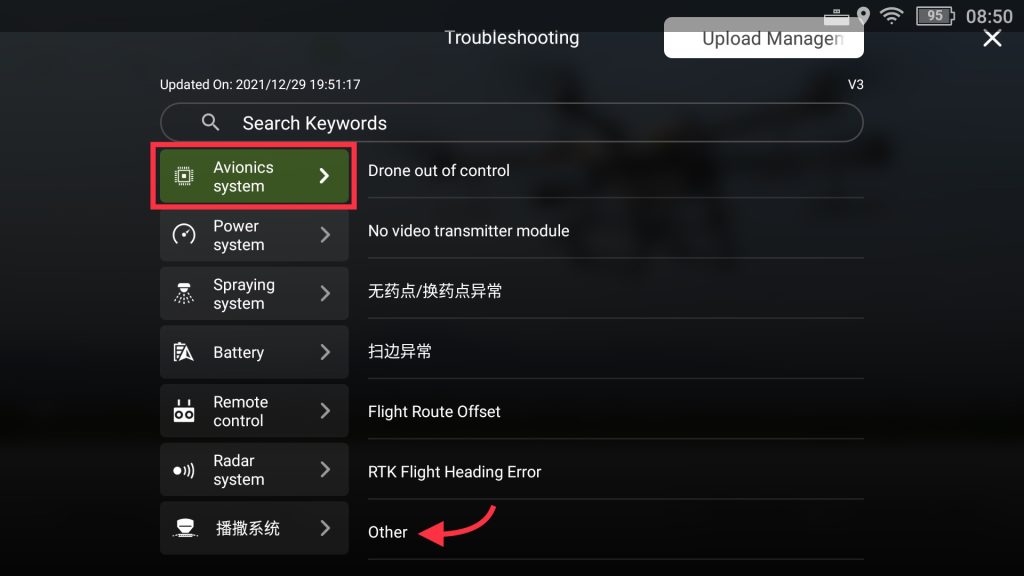

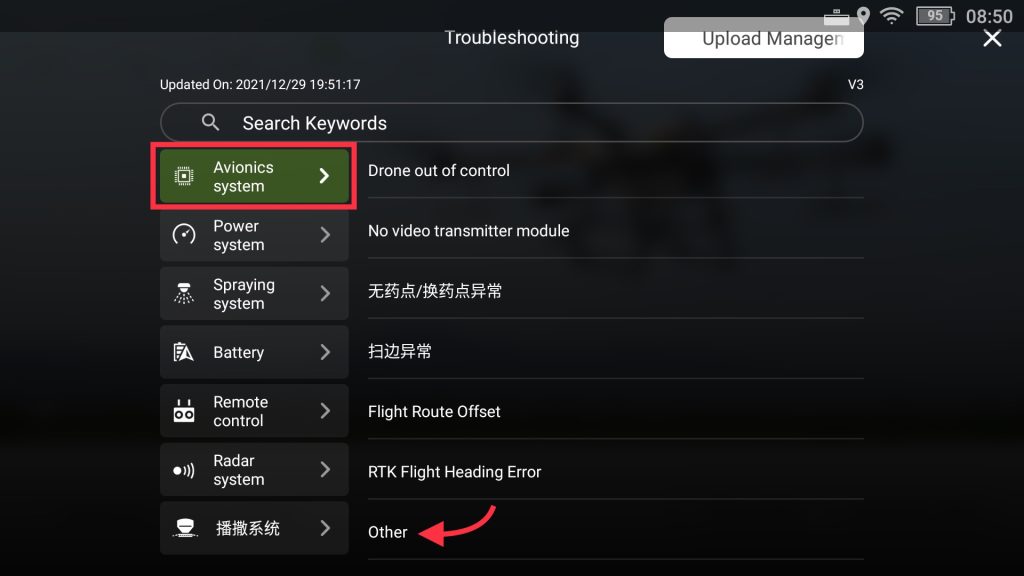

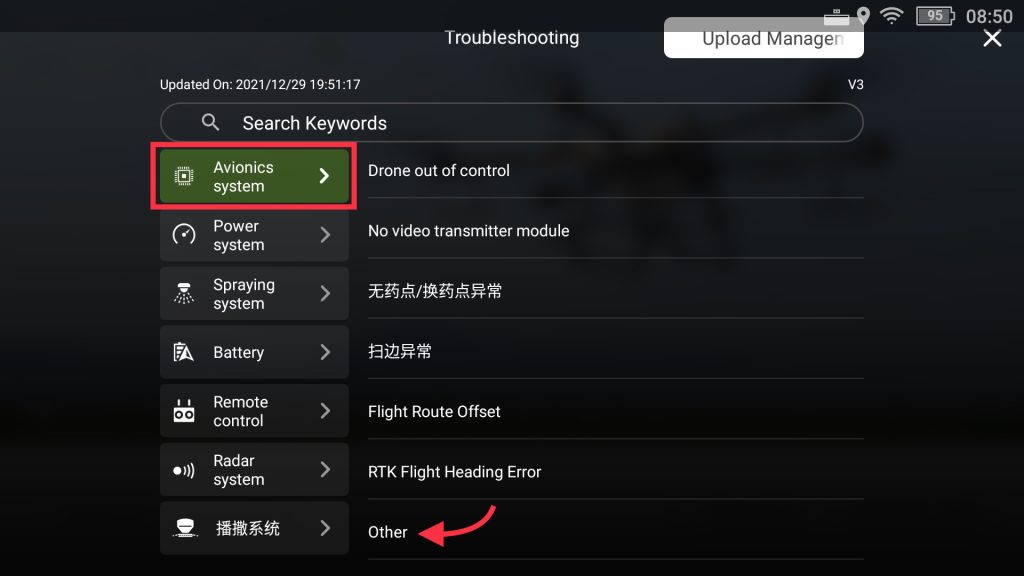

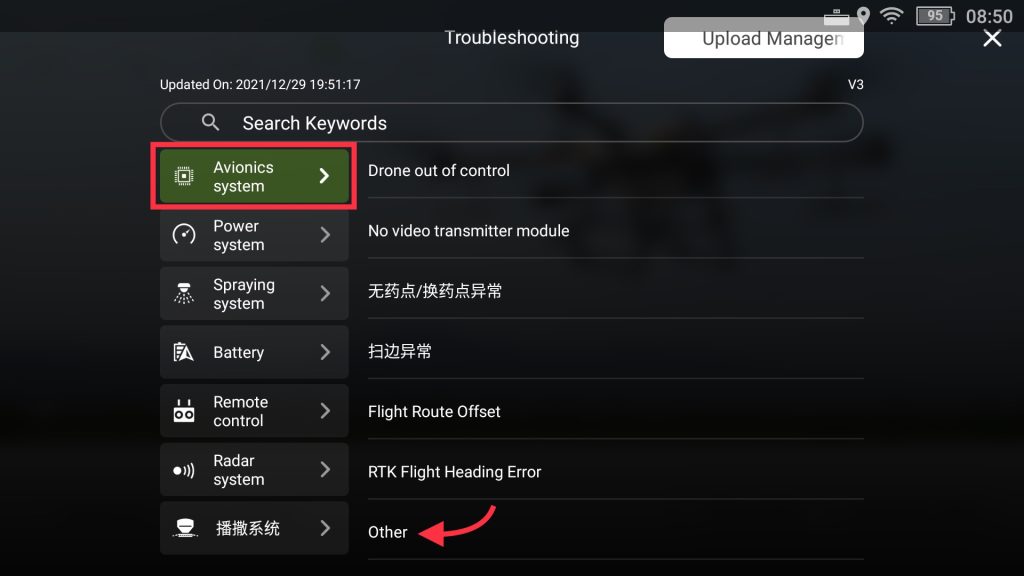

- It is necessary to provide data from “Avionics System” -> Other

2. In case of abnormal radar functionality

- It is necessary to provide data from “Avionics System” -> Other & Radar System -> Other

- Photos of the surroundings where the error occurred, e.g. trees that the drone was unable to avoid, obstacles or power lines

3. In case of RC (controller) abnormalities such as black screen display, joystick error and system crash

- Video recording of the error

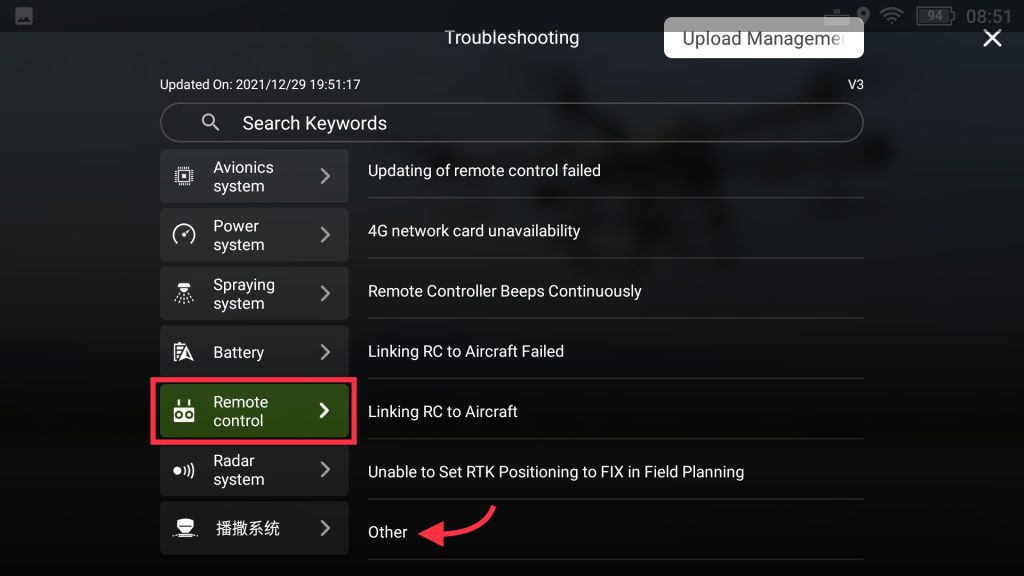

- It is necessary to provide data from “Remote Control” -> Other

4. In case of abnormal transmission and image control such as connection loss, screen freeze

- It is necessary to provide data from “Avionics System” -> Other & Remote Control -> Other

- Video recording of the error

5. In case of abnormal APP functionality

- Video recording of the error

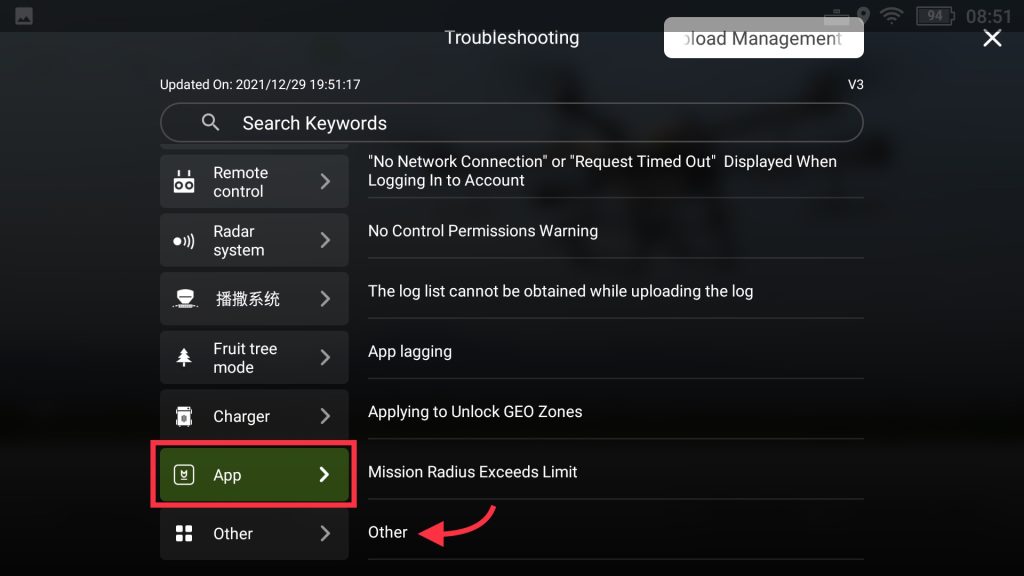

- It is necessary to provide data from “APP” -> Other

6. In case of firmware update failure

- Video recording of the error

- It is necessary to provide data from “Avionics System” -> Other

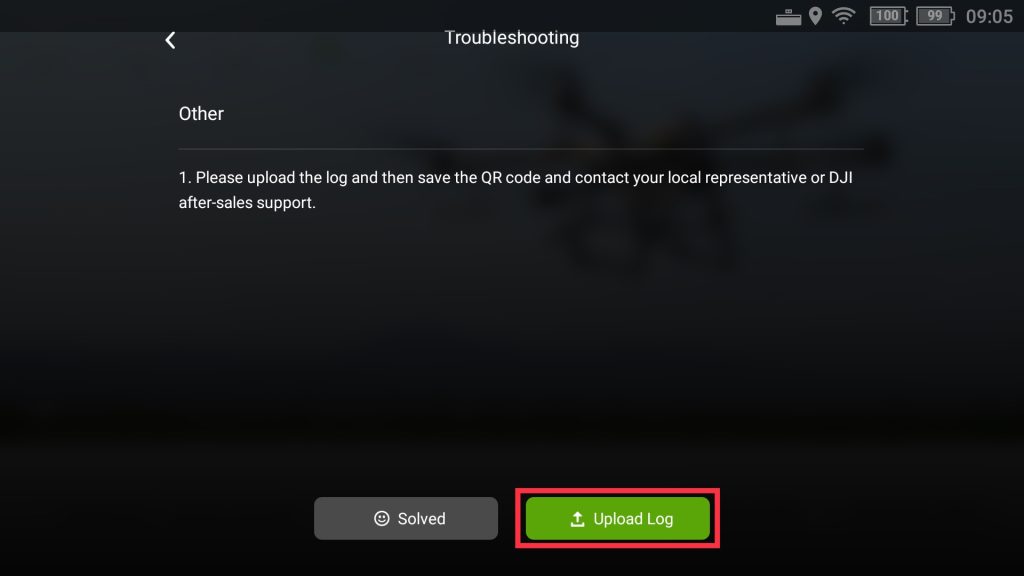

- After selecting the correct error category, you need to upload the logs

- Clicking on “Upload logs” will display a list of saved logs from recent flights and drone handling

- It is necessary to select the correct log (according to the time when the error occurred) and upload it

- After the data is processed, you will see a QR code, you need to record it with a screenshot and then send it to an authorized service center

After receiving the data from the client, the authorized service investigates the event and then evaluates it as:

- Pilot error, which is not covered by the warranty period (if the equipment is still under warranty) and the service will be performed at the client’s expense

- Defective equipment covered by the warranty (if the equipment is still under warranty) and service will be performed at DJI’s expense

In order to clarify the rules of spray drift by agricultural drones (or drones) under different influencing factors, also to guide agricultural drones to safely and efficiently carry out crop protection operations and to ensure safety for non-target organisms and the environment, a spray drift test was carried out with a DJI Agras T30 drone.

The test was conducted at the test site of the Chinese Academy of Agricultural Sciences. A DJI Agras T30 agricultural drone was used for testing. The terrain on which the test was conducted was flat and the surrounding area was open, free of obstacles. The flight speed of the T30 drone was selected as 3 m/s, 4 m/s, 5 m/s and 6 m/s. The flight height can be selected as 2 m, 3 m and 4 m. It is also possible to choose between normal and coarse drop size. Each combination of parameters was used to measure the droplet deposition and spray drift of an agricultural multi-rotor drone at three different crosswind speeds. The test was carried out on an area of 128 m x 125 m (length x width). Six sampling strips were arranged in the sampling area with an interval of 5 m between each sampling strip. The first and last sampling strip were 50 m from the edge of the test area. The sampling area includes 0-20 m in the operational area and 0-50 m in the downwind drift area.

After application, wait 5-10 minutes, then check that all droplets on the filter paper are dry, put them in order in zip-lock bags and store the samples in a dark and cool place. Later, the samples are processed and measured. The agricultural drone is set to auto operation mode with multiple applications, and the flight path of the drone is 125m long to ensure that the agricultural drone in the sampling area will fly at a constant speed. An aqueous solution of Rhodamine B at a concentration of 5 g/l was prepared prior to the test. Subsequently, the drone was filled to 50% capacity, so up to 15 l. Before the test it is of course necessary to check the functional condition of the drone nozzles and the flow calibration. After the wind direction meets the requirements and stabilizes, the drone will take off with the auto-flight button, apply RTK, and return to the takeoff location from the upwind direction after spraying.

Analysis and conclusion of testing

- Effect of crosswind velocity on drop drift:

Crosswind speed is the most important factor affecting the drift distance and the amount of drifted droplets, and the best operating condition is when the crosswind speed is less than 3.4 m/s.

- Effect of flight height on droplet drift:

When the crosswind speed is in the range of 0-3.4 m/s and the flight height is 2 m, 3 m and 4 m, the amount of settled spray droplets in the operating area gradually decreases, the uniformity of droplet distribution deteriorates, and the droplet drift distance gradually increases. When the crosswind speed is greater than 3.4 m/s, the change of working height has almost no effect on the droplet deposition and drift, and the main influencing factor is the crosswind speed.

- Effect of ambient temperature and humidity on drift:

The effect of humidity on droplet drift is more significant provided the ambient temperature is 15-30 °C, the crosswind speed is less than 3.4 m/s and the humidity is in the range 20-80 %. As the ambient humidity increases, both the amount of drift and the drift distance decrease.

The optimum ambient humidity range to reduce fog drift is: ambient humidity above 60%. When the ambient wind speed reaches more than 3.4 m/s, the change in ambient temperature and humidity has no significant effect on droplet drift.